Office: (925)207-0439

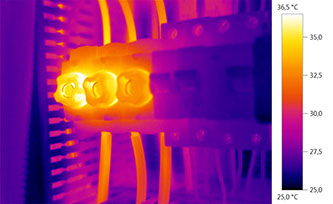

Infrared thermography is an ideal inspection technique for detecting and documenting defects within energized electrical systems. Performed properly, infrared inspections can detect evidence of loose or deteriorating connections, overloaded circuits, open circuits, imbalance loads, and defective equipment. Many electrical defects are accompanied by a change in operating temperature prior to the failure.

Infrared inspections may be applied at any location from the point of generation to the point of usage, provided that the subject components are underload and visually accessible. All detected exception or potential issues should be investigated for cause and correction as soon as possible regardless of the operating temperature.

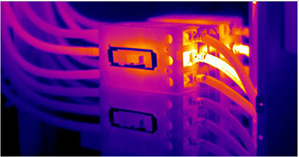

Infrared thermography is noncontact and requires no interruption of service. It is recommended that infrared inspections be performed at least annually with the electrical system under normal load. More frequent inspections should be performed where warranted.

Infrared inspections are used to complement a routine preventative maintenance program. Infrared inspections are never designed to replace required maintenance procedures.